what is hardness test for tablets|hardness test procedure for tablets : online sales Hardness Test: Principles and Methods. What is tablet hardness? "Tablet hardness" is a measure of the force required to break a tablet in a test apparatus that places the tablet under a . Abrir Conta - Jogos Santa Casa - Últimos Resultados - M1lhão

{plog:ftitle_list}

Resultado da MARTINA OLIVEIRA. (483 results) Martina Oliveira Avalia o Pauzão do Ruan, ela ficou com tesão vendo! - Podcast Pápum no Barraco! COMPLETO NO SHEER - XV RED. Martina Oliveira Mostra o seu corpo com detalhes e o biquinho dos peitos, ela se molhou! - Podcast Pápum no Barraco! .

Hardness and friability are important physical parameters for a tablet. These parameters ensure the strength and structural integrity of a tablet for transportation, packaging and handling before usage.Hardness Test: Principles and Methods. What is tablet hardness? "Tablet hardness" is a measure of the force required to break a tablet in a test apparatus that places the tablet under a .

Generally, oral tablets have a hardness of 4 to 10 kg. However, ODT tablets and chewable tablets have less hardness and often sustained-release tablets are much harder. . Crushing, fracturing, and bending tests quantify hardness. Solid tablets are perhaps the most commonly used dosage form for pharmaceuticals. Tablet hardness serves .What is Hardness Test and Why it so important? Tablet Hardness Testing is also known as the “Crushing Strength Test“. Tablets must have a specific level of strength or hardness in order to withstand mechanical shocks during .

The breaking force of tablets is commonly called hardness in the pharmaceutical literature; however, the use of this term is misleading. In material science, the term hardness refers to the resistance of a surface to penetration or indentation by a small probe. The term crushing strength is also frequently used to describe the resistance of tablets to the application of a compressive . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .Tablet hardness testing is a critical quality control parameter that ensures the tablets meet the required specifications and maintain their structural integrity during handling, transportation, and usage. Scope. This SOP applies to all personnel involved in tablet hardness testing within the pharmaceutical company.

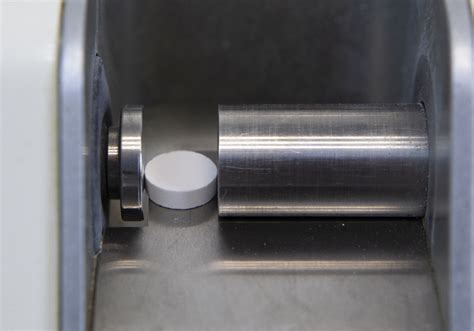

Water hardness test kits may use water hardness test tablets or paper test strips (see below). When mixed with (a test tablet) or wet by (a test strip such as those shown at left) water of a specified volume (fill the test bottle with the specified amount dictated by the test kit instructions or to the line marked on the test bottle), the water .Testing of all tablet shapes, sizes, and materials. The open and accessible test area allows for simple tablet handling by the operator – and doesn’t limit the flexibility of the MT50 to measure virtually all types of tablet shapes, sizes, and materials.From standard tablet hardness tests to tensile strength and three-point flexure testing, the MT50 allows to perform different test types . The tablets are then placed between the platens of a tablet hardness tester, and test parameters, such as the rate of force application, are set according to the testing standards or specifications. During the test, the tablet hardness tester applies a controlled force to the tablet until it fractures or reaches the desired deformation level.

The hardness tester is a testing instrument used to measure the hardness of solid tablets. It is suitable for large and medium-sized pharmaceutical factories, hospitals, schools, drug inspection departments and other units .

tablet hardness testing standards

Hard ness Test for Tablets Teledyne LABS offers both manual and automated tablet hardness testers. Tablet hardness testing is a method of determining mechanical properties of a drug product, typically oral dosage forms such as a solid dose tablet. Tablet breaking force (commonly called tablet hardness) is a crucial characteristic in the manufacture of solid dose formulations. Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time). Friability test of tablets (uncoated) Sample requirement: For ≤ 650 mg weight of tablets, take 6.5 g tablets or as near as possible to 6.5 g. For tablets with more than 650 mg weight, take 10 tablets. Before testing, tablets must be cautiously dedusted. Friability Test Apparatus [2, 3] Tablet Hardness Test Is Official Or Non-Official Test. In-process tests for tablets are divided into two categories one is the official test and the other is the non-official test. As for as tablet hardness test is concerned it comes under the category of Non-Official test. How To Check Tablet Hardness?

The equation determines the diametral tensile strength (σ t): (1) σ t = 2 P π d t where P is the load at failure, d is the diameter and t the thickness of the thin circular disc. Eq. (1) can be applied to flat cylindrical tablets provided the test conditions result in the tablets failing in tension i.e. test conditions must ensure that the .A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet hardness testers with precision Dr. Schleuniger® measuring technology, standard-setting user friendliness, and robust Swiss .

Another common fracture test on tablets is the snap or bending test. This test is common for an oval tablet shaped like a capsule (i.e., caplet) as well as on a fairly large round tablet. . These tablet hardness tests provide a meaningful picture as to the amount of force required to fracture the solid-dose tablet. This knowledge will be .

Palintest offers both visual and digital test methods for measuring calcium hardness. For testing calcium hardness in pools, we have a range of pool photometers. Palintest’s Pooltest 25 Photometer covers the complete range of water testing parameters making it the ideal choice for pool and spa management. It enables full disinfection and .Pharmaceutical tablet hardness testing (or more correctly known as diametral/diametrical crushing strength) is a way of measuring the quality of tablets. Merlin uses tablet hardness testing to calculate the tensile strength .A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet hardness testers with precision Dr. Schleuniger® measuring technology, standard-setting user friendliness, and robust Swiss . Testing tablet hardness is ensuring the mechanical integrity of produced tablets during subsequent processes. Hardness of a tablet directly relates to pharmacokinetics as disintegration time .

Hardness Test: For this test one of the earliest testers was the Ketan tablet hardness tester, which is a type of the Monsanto hardness tester to evaluate tablet hardness tester. The tester consists of a barrel containing a compressible spring held between two plungers. The lower plunger is placed in contact with the tablet and zero reading is . 11. Note: • As per official standard,tablet thickness variation alloted upto (+ or -) 5% of standard value. 4.HARDNESS TEST: • This test is also known as “Crushing Strength Test”. • Tablets require a certain amount of strength, or hardness to withstand mechanical shocks of handling in manufacture, packaging and shipping • Tablet hardness has been . Tablet Hardness. Tablet hardness is directly proportional to the applied pressure using compression wheels meaning if we apply more pressure hardness is increased & vice versa. If we keep all other factors constant i.e tablet weight & die filling volume, tablet thickness again may vary depending upon the tablet hardness or applied compression .The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. Used for materials with a coarse or inhomogeneous grain .

An index has been developed that factors tablet hardness with the load to break that tablet to create a numerical value that can be used to compare chewable tablets for their ease of being chewed.Introduction to Tablet Hardness Testers and Testing. The term tablet hardness is commonly used in the pharmaceutical and nutraceutical industry. However, Tablet hardness is somewhat misleading in that hardness is more accurately defined as the ability of a material to resist the penetration of a probe. Found in USP Chapter <1217> “Tablet .

4. Dissolution test: Drug should be released from tablet in a controlled and reproducible way. Weight variation, thickness & diameter: The appearance of tablet should be elegant & its weight, size & appearance should be consistent. Hardness & friability: The tablet should show sufficient mechanical strength to withstand fracture & erosion during manufacture . This apparatus and operation is clearly defined in the USP and provides a good quality check for tablet durability. This testing is an excellent in-process check to monitor the consistency of the tablets in the production run. USP Tablet Breaking Force <1217> is commonly referred to as hardness testing.

tablet hardness tester types

Seja bem vindo Entre com o usuário e senha Login. Esqueci minha senha

what is hardness test for tablets|hardness test procedure for tablets